Holding a router in a purpose-built table provides a quick way of creating mouldings and rebates, even slot-together door frames using multi-cutter profile sets. The JessEm Rout-R-Lift Prestige helps to make this easier – here, Jonathan Salisbury takes a closer look.

The Woodworker & Good Woodworking

Plunge routers are very useful power tools, with a huge variety of cutters – from straight to exceedingly complex profiles. When hand-held they require sufficient material width to support the base, otherwise the router will tip – with potentially disastrous consequences for material and user.

When it’s difficult to control the router from the top, it can be held upside down, in a frame, and the material moved into the cutter. This requires a purpose-built table and can be exceptionally dangerous, particularly if you have little experience pushing wood into a fast-spinning, exposed cutting edge.

The height needs to be easily adjustable, sometimes to very fine tolerances, and maintained throughout the cut. Vibration and cutters that drop on their own must be avoided. It’s possible to rely on the router’s plunge and depth stop alone to set up the height, but it can be difficult to achieve consistent, repeatable accuracy. You’ll also be fighting against gravity.

A router with a rack plunge is easier, but still awkward to set from underneath the table top. When cutting separate profiles that need to match exactly, you also need fraction-of-a-millimetre precision. The Triton MOF001 dual mode precision plunge router is an ideal unit for basic upside-down use as its built-in micro height adjuster can be operated remotely with a handle. But beyond anything simple, it ought to be mounted in a proper lift attached to an appropriately-sized, sturdy table.

A lift raises and lowers the cutter through a hole in the table using a fine, threaded bar turned by a handle, usually from the top.

To provide adequate travel, the router is locked, fully-plunged, in its own frame.

First look

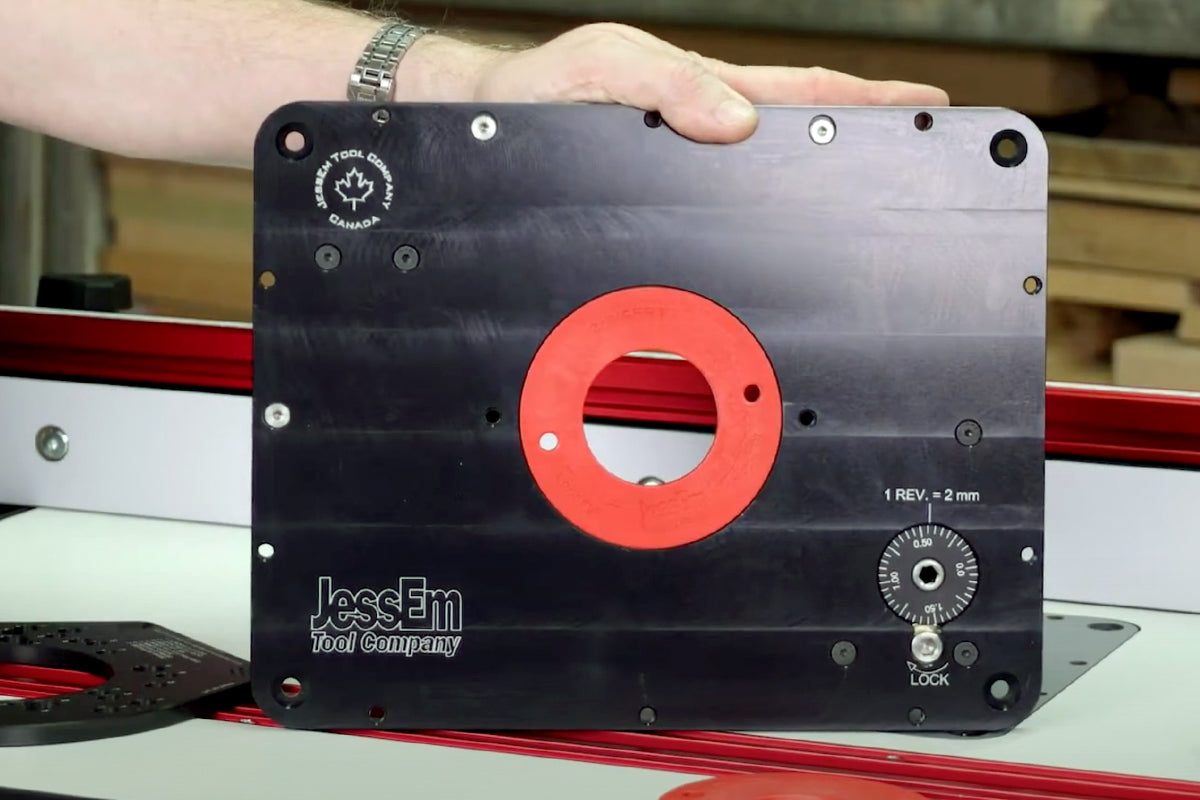

The JessEm router lift provides a quick and easy way of turning your router into a table-top moulding machine. Compact and solidly built, three posts hold and guide the router up and down. These are perfectly aligned to provide parallel travel, while the long guides ensure that there’s no twist at all. If alignment has moved in transit, it can be set back to ‘factory condition’ with the turn of three small screws.

Lift action is super-smooth and precise, even when changing direction. The finely-finished screw has an anti-backlash nut, which means there’s no need to turn against the direction in which you wish to move, to take up slack and ensure that you end up with a setting as close as possible to where you want to be. A 2mm lift per complete rotation means you can count turns to get the cutter more or less in the right place and the clearly marked scale around the adjustment screw gives 0.05mm increments to help guide you for most of the rest of the way. A separate gauge will always be required to ensure that the tip of the router cutter is exactly the desired height from the table top. The adjacent lock screw has an arrow printed around it to indicate the direction it needs to turn and uses the same handle as the height adjustment to prevent any movement. The handle may seem unnecessarily long, but in use you need to be clear of the guards, fences and material on the table top.

Setting up

Almost all router cutters now have a depth mark to show how far they need to be pushed into the collet, allowing them to be tightened properly and prevent them from coming loose during cutting. I’ve seen lifts where the maximum height of movement isn’t sufficient for a correctly inserted cutter to protrude above the surface as required, but this isn’t an issue with the JessEm. The mounting plate comes right up to the under-surface of the metal plate that fits into the table recess. The access hole for changing cutters is adequate but a collet extension would be a worthwhile addition; it can be a fiddle to access the spindle lock. Three insert rings close the hole around the cutter for maximum support, which secure using ‘Tab-loc’ – a bayonet-style system that requires a partial turn of the removable spanner. There’s also the option to install a start pin in the top, close to the cutter, to help guide the wood more safely at the beginning of a cut.

The router attaches to the plate using the same screw positions as its own baseplate, which you must remove. The pre-drilled plate has all the necessary holes in the correct positions for a range of Hitachi, DeWalt, Bosch, Makita and Festool models, but not my Triton, so the blank plate model would be my choice. It’s easy enough to use the router’s baseplate to position the required holes for any router, but if yours is already catered for, the pre-drilled plate isn’t more expensive and saves a lot of time when it comes to setting up.

Installation

When installed in a table, the lift hangs from the top-plate. This needs to be attached securely so it’s flush with the surrounding table top, to ensure there’s a level surface over which wood will travel up to and beyond the cutter. If you have experience making workbenches, this is easy enough to do, but to make this somewhat quicker, a range of pre-fabricated tops is also available. These are worth considering, as the hole for the top-plate will be the perfect size and shape, lined with a steel gasket – also available separately – for the 10 height-adjusting socket screws to rest on, which have threaded holes in each corner to secure the lift to the table.

Conclusion

Turning a router upside down to make it easier to use for mouldings and certain other processes is seemingly simple, but involves a lot of preparation. Even when set up properly, with extraction, guards and stop switches in the right places, this is a process that must be taken seriously. The JessEm lift would certainly be one to consider for anyone progressing to this stage of machine operation, if you have a router to spare – if not, Wood Workers Workshop have dedicated systems, too.

There are other, cheaper ways to achieve something similar, but in my opinion, if you’re serious about table-routing, it really is worth spending the money to do it properly from the outset. The ease of use, smooth operation and secure holding of the Rout-R-Lift are worth the initial outlay and, when built into a solid table, will provide years of reliable service.

Specification

- Allows the mounting of a plunge router with minimal (14.5mm) height loss

- Direct-drive rise and fall screw mechanism for endless years of accurate and reliable service

- Mechanisms are located towards the front, allowing adjustments without moving the fence

- A metric scale built into the router plate’s surface gives accurate incremental calibration of the rise

- Height adjustment and lock are operated using the same cranked handle

- Solid 9.5mm-thick precision ground, anodised aluminium top-plate won’t flex or bend in use

- Built-in levelling system allows for perfect alignment and fit

- Accommodates cutters up to 90mm diameter

Includes

- JessEm Rout-R-Lift Prestige

- Winding handle

- 3 × Tab-loc insert rings and tool

- 10 levelling grub screws

The Verdict

- Pros: Exceptionally high quality, sturdy and reliable unit; pre-drilled plate for the most popular routers; smooth and precise action and solid locking mechanism allows precise placement of router cutter; unit arrives ready to install

- Cons: None – except that quality comes at a price!

- Rating: 5 out of 5