Harvey T-40 Woodturning Lathe with Cast Iron Legs, Outrigger and Extension Bed

- Warranty: 1 Year & Lifetime Customer Support

- Price Match Promise

- Order by 2pm for Same Day Dispatch – Mon to Fri

- 45 Day Hassle-free Returns

- Worldwide Shipping | No Hidden Costs

Harvey T-40 Woodturning Lathe with Cast Iron Legs, Outrigger and Extension Bed is backordered and will ship as soon as it is back in stock.

Description

Description

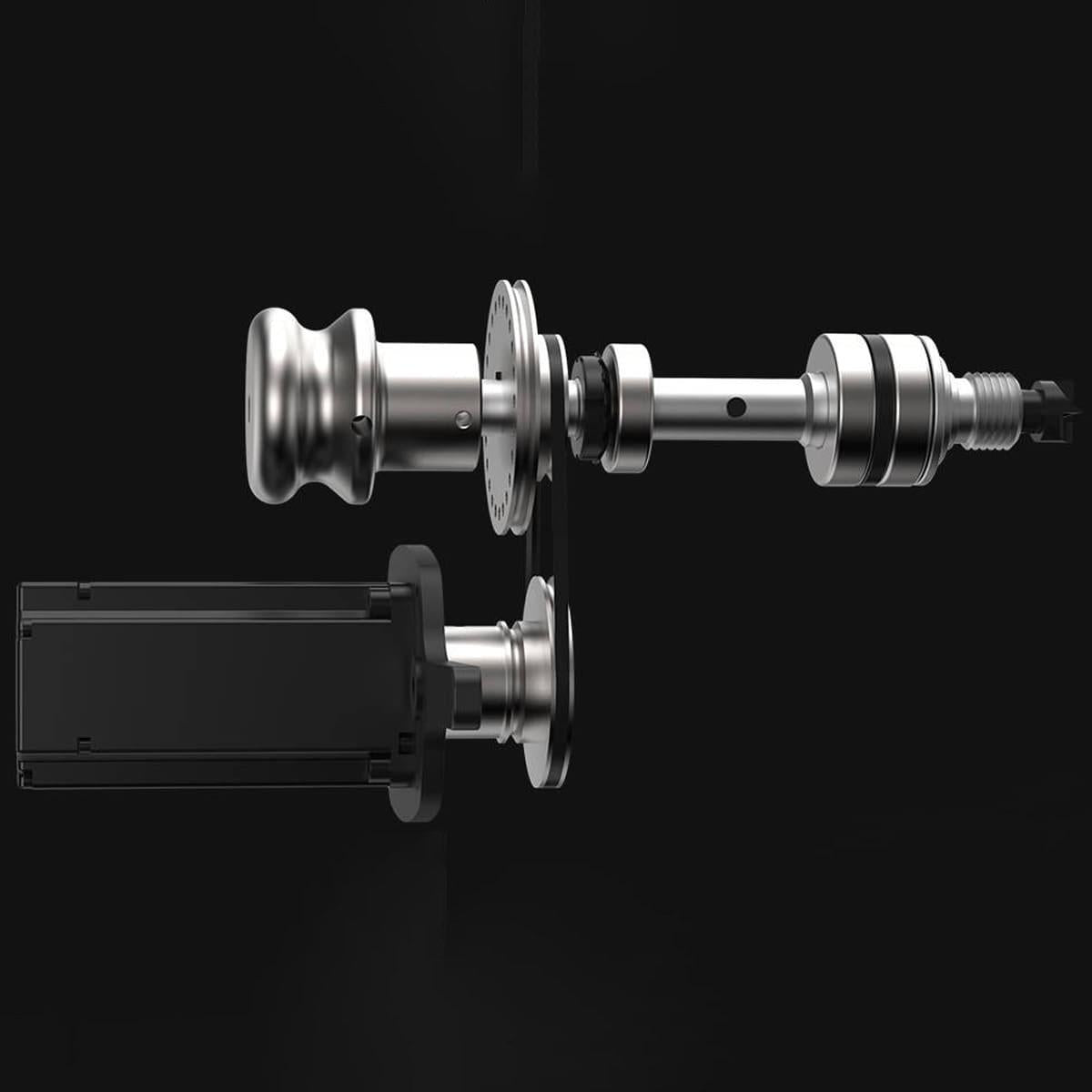

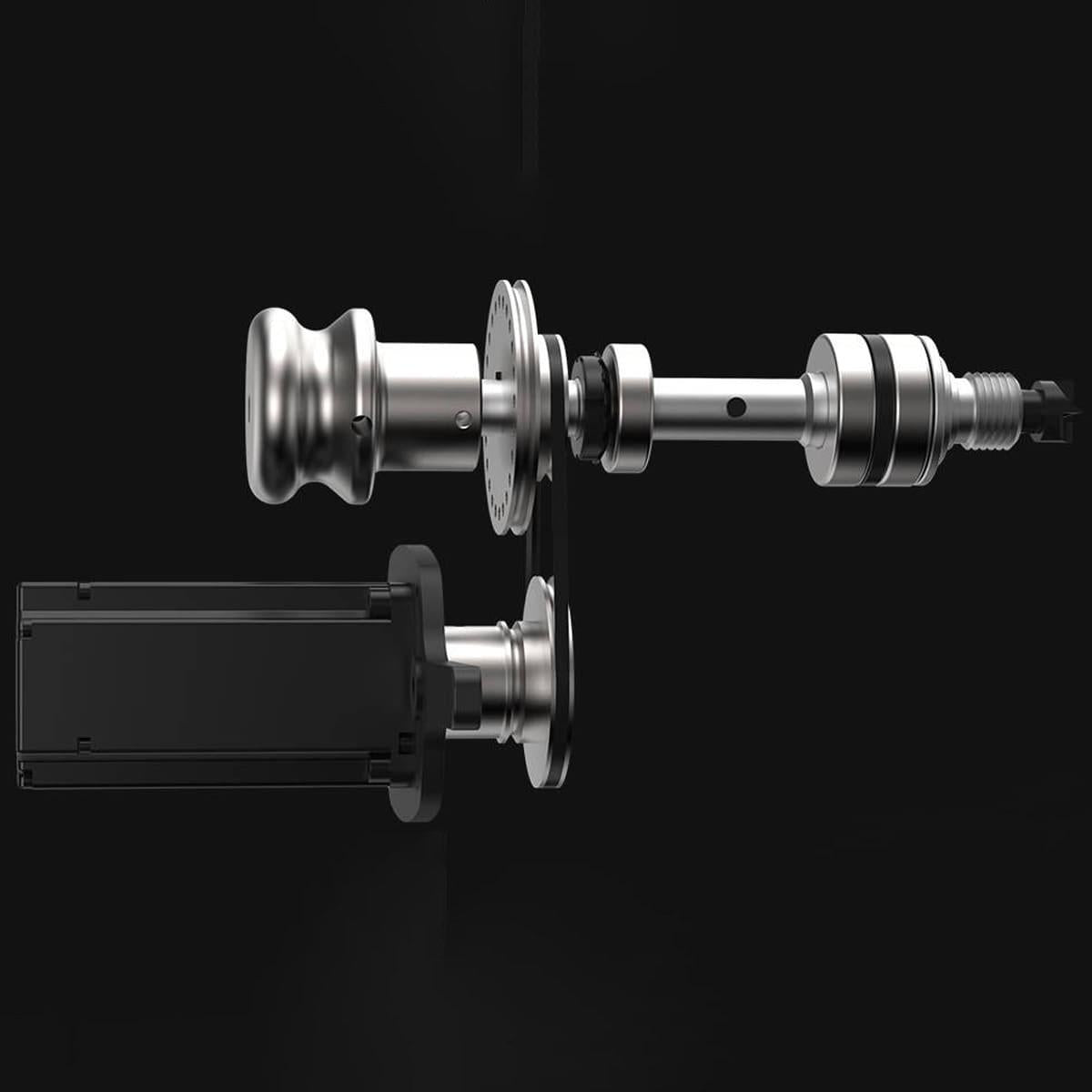

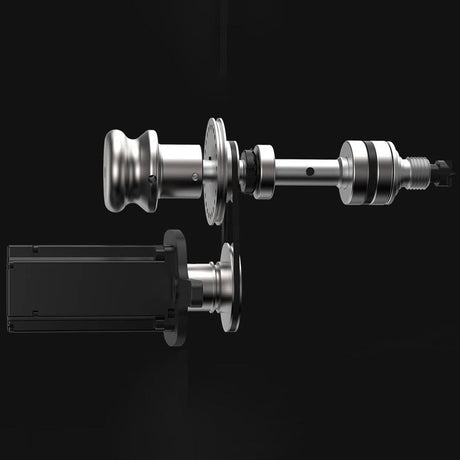

The T-40 14” x 24” benchtop lathe incorporates an Industrial Servo Motor, commonly used on metal working lathes for its powerful torque, which allows the T-40 huge torque at low speeds. The spindle speed is constantly monitored with instant response to increase or lower the power output. The servo motor can provide up to 2.2kW at its peak, an incredible 12.54 Nm (Newton Meters). This means that the T-40 is capable of handling even the most challenging of cuts.

With heavy-duty casting but a compact footprint, this lathe will fit in even small workshops. A digital readout shows the current spindle speed, the spindle can also be switched to run in reverse direction.

Features

- Spindle capacity 610mm (24″)

- Bowl capacity 360mm (14″)

- Variable speed Servo Motor 60-4300rpm

- Digital speed readout

- 24 position spindle indexing

- Spindle thread size M33 x 3.5mm

- Spindle taper MT2

- Rotating headstock for outboard turning

- 2-year warranty

Cast-Iron Bed

The cast iron bed is precision ground with a polished finish. The width is 160mm to inspire confidence when making heavier cuts. There are 8 holes in the base for securing the lathe to a bench.

Rotating Headstock

The headstock rotates 90 degrees, to enable the turning of larger diameter bowls. There are preset locking positions at 0, 22.5, 45 and 90 degrees. When used at 90 degrees with the optional outboard turning attachment, the bowl capacity is increased to 457mm (18″) in diameter.

Ergonomic Tool Rest

The Cam lock mechanism has brass bushings for a smooth action. The tool rest height locking level has a brass tip to give an accurate placement and reduced wear without damaging the tool rest post. The shape of the 300mm (12”) tool rest has been designed for operator ease and comfort. It has a hardened round steel bar running across the top edge to ensure turning tools slide comfortably along its edge.

Solid Tailstock

The cast iron tailstock has a cam lock action with a brass guide bush to produce a smooth action with minimal wear. A metal hand wheel is used to wind the quill in & out, with a travel of 100mm and automatic centre removal.

Upgraded Live Centre

The heavy-duty live centre is made of carbon alloy tool steel. With its hardness, resistance to abrasion, and ability to retain shape at increased temperatures, the live centre offers stability and accuracy.

Upgraded Handwheel

The handwheel of the headstock has a large size and smooth finish, allowing the spindle to be rotated manually. Built into the headstock is a 24-position indexing system, allowing the spindle to be locked in 15-degree intervals to apply finishing details.

Includes

- Knockout bar

- Locating rod

- 4 Prong drive centre

- Live centre

- 75mm diameter faceplate

- Service tools

- 3Mtr cable with UK 3 pin plug

CI-40 Cast-Iron Legs

A pair of heavy-duty cast-iron legs made perfectly for the T-40. They are designed to reduce vibration and spread the footprint to 600mm. There are 4 adjustable feet to adjust to an uneven floor. When mounted on these legs the spindle height is at 1100mm.

OT-40 Outrigger

Consisting of machined steel components, this attachment will allow larger diameter bowls to be turned up to 457mm (18″) diameter. The headstock of the lathe is rotated through 90 degrees, a swing arm extends away from the bed with an extended tool rest holder. The standard tool rest then sits in the extension arm and can be positioned to the front or the side of the workpiece as required. Any tool rest with a post diameter of 1″ can be used.

EB-18 Extension Bed

One piece cast iron, machine ground extension piece. Increasing spindle capacity by 75% to 1067mm (42”).

Delivery & Returns

Delivery & Returns

Same-Day Dispatch

Orders placed before 2pm (Monday–Friday) are usually dispatched the same day. All deliveries are fully trackable.

UK Mainland Delivery Options

| Service | Delivery Time / Notes | Price |

|---|---|---|

| FREE UK Delivery | 1–2 days — orders over £85 | FREE |

| Economy Delivery | 2–3 days | £4.50 |

| Standard Delivery | 1–2 days | £5.95 |

| Express Next Day | Next working day — orders placed by 2pm (Mon–Thurs) | £7.99 |

| Express Pre-Noon | Next working day before noon — orders placed by 2pm (Mon–Thurs) | £15.95 |

| Saturday Delivery | Saturday delivery — orders placed by 2pm Friday | £25.50 |

| Click & Collect | Open for collection: 9am–4:30pm (Mon–Fri) | FREE |

Important information

- Express Pre-Noon and Saturday services aren’t available to Northern Ireland, Scottish Highlands, Islands or remote postcodes — Express Next Day takes 2 days and other services may be slower.

- Large or heavy items may not qualify for Express Pre-Noon or Saturday delivery to your area — we’ll contact you if this applies.

- Click & Collect – Collection available after you receive “Ready for Pickup” email — most orders before 2pm are same day.

International Delivery

We ship worldwide to over 200 countries. No hidden costs — all duties and taxes are calculated at checkout.

Harvey Machines & SawStop Delivery

Harvey Machines and SawStop products are shipped directly. Once your order has been placed, delivery confirmation and tracking details will be provided by the manufacturer.

Hassle-free Returns

All orders are covered by our 45-day Hassle-free Returns guarantee.

Why Buy From Us?

With over 1 million tools sold worldwide, Wood Workers Workshop has been trusted by woodworkers since 1999.

We offer 45 Day Hassle-Free Returns, giving you extra time — and complete peace of mind — to make sure it’s right for your workshop.

Read our story here.

-

“Wood Workers Workshop is widely respected for the depth and reliability of its expert woodworking advice.”

-

“Peter Sefton brings a furniture maker’s eye and decades of experience to the tools offered by Wood Workers Workshop.”

Explore The Range

View all

We are Wood Workers Workshop

We are a family business, run by woodworkers for woodworkers, delivering 5-star customer service since 1999.

Stocking a wide range of woodworking tools from leading brands: AUKTools, Milescraft, INCRA, iGaging, JessEm, Woodpeckers, FastCap, Verum & more.