Clifton No 5 Jack Plane

- Warranty: 1 Year & Lifetime Customer Support

- Price Match Promise

- Order by 2pm for Same Day Dispatch – Mon to Fri

- 45 Day Hassle-free Returns

- Worldwide Shipping | No Hidden Costs

Clifton No 5 Jack Plane is backordered and will ship as soon as it is back in stock.

Description

Description

Clifton e - No 5 Jack Plane is the "jack of all trades", a mid-sized plane that can be used for smoothing and flattening medium sized timbers. Clifton Bench Planes are crafted from the finest materials and hand finished in Sheffield - the body and frog are made from accurately machined grey cast iron with their sides and sole fully ground. This is the smaller of the Jack Planes in the Clifton Bench Planes range.

Clifton Plane cutting irons are made from O1 Steel. This bench plane's cutting iron is 2" wide and 3mm thick, increasing rigidity, with a hardness of 60-62 Rockwell C, and the cryogenic treatment means that these blades will hold their edge even longer. Clifton blades have a reputation as quick to hone whilst producing one of the finest sharp edges available ... the utopia that all blade makers strive for!

The Frog and Frog Seating in the body of these Bench planes is based on the Bedrock design, first seen on early Stanley planes, meaning the seating pad in the body is fully machined flat to mate with an equivalent full face and machined, underside of the Frog. This ensures absolute stability of the Frog, providing a firm and solid surface for the cutting iron, which again rests on a fully machined upper side of the Frog. When used with the extra thick Clifton Cutting Iron and Clifton Two Piece Cap Iron, this design has probably the most rigid and effective clamping mechanism of any Bench plane available.

The accuracy of this mechanism allows for the Cutting Iron to be advanced to give a virtually "Zero" mouth opening, allowing the finest shavings to be taken even on the most difficult of timbers. The Bedrock design uniquely allows the mouth width to be adjusted without dismantling the Frog and Iron assembly.

So, to adjust the mouth width, the Frog should be moved backwards or forwards by loosening the outside two of the three screws located at the back of the Frog seating pad (underneath the adjusting wheel), then turning the central screw either clockwise to close the mouth or anti-clockwise to open.

The Cap Iron is a one piece design giving rigid clamping and the Frog locating pins and screws are made from polished and ground stainless steel. The Lever Cap is made from grey polished Cast Iron with the Screws and Adjusting Wheel from polished brass. The Y Lever is a solid one-piece casting and the Adjusting Lever and most other components are made from polished stainless steel.

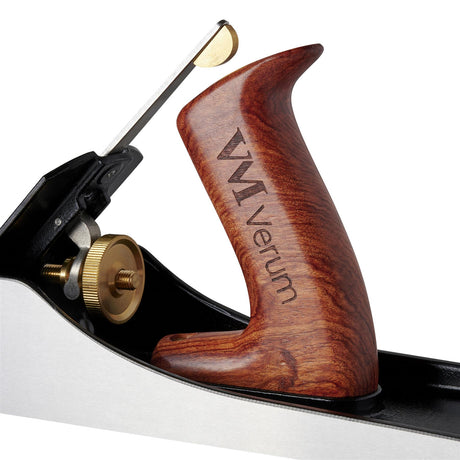

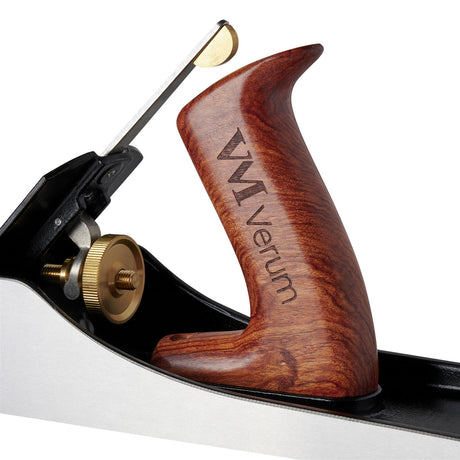

The Knob and Handle are carefully shaped from Bubinga hardwood sanded to fit your hand perfectly and sealed giving a very tactile and comfortable plane.

Peter Sefton, owner of Wood Workers Workshop, is very proud to have been part of the development team when the new cryogenically treated high carbon steel blades used in Clifton Planes were developed. His working knowledge and experience of sharpening and woodworking helped develop the improved plane blades that are presently in production and made entirely in Sheffield.

Blade: Carbon Steel O1 - 3mm (0.120") thick cryogenically hardened to 60-62 Rockwell C

Delivery & Returns

Delivery & Returns

Same-Day Dispatch

Orders placed before 2pm (Monday–Friday) are usually dispatched the same day. All deliveries are fully trackable.

UK Mainland Delivery Options

| Service | Delivery Time / Notes | Price |

|---|---|---|

| FREE UK Delivery | 1–2 days — orders over £85 | FREE |

| Economy Delivery | 2–3 days | £4.50 |

| Standard Delivery | 1–2 days | £5.95 |

| Express Next Day | Next working day — orders placed by 2pm (Mon–Thurs) | £7.99 |

| Express Pre-Noon | Next working day before noon — orders placed by 2pm (Mon–Thurs) | £15.95 |

| Saturday Delivery | Saturday delivery — orders placed by 2pm Friday | £25.50 |

| Click & Collect | Open for collection: 9am–4:30pm (Mon–Fri) | FREE |

Important information

- Express Pre-Noon and Saturday services aren’t available to Northern Ireland, Scottish Highlands, Islands or remote postcodes — Express Next Day takes 2 days and other services may be slower.

- Large or heavy items may not qualify for Express Pre-Noon or Saturday delivery to your area — we’ll contact you if this applies.

- Click & Collect – Collection available after you receive “Ready for Pickup” email — most orders before 2pm are same day.

International Delivery

We ship worldwide to over 200 countries. No hidden costs — all duties and taxes are calculated at checkout.

Harvey Machines & SawStop Delivery

Harvey Machines and SawStop products are shipped directly. Once your order has been placed, delivery confirmation and tracking details will be provided by the manufacturer.

Hassle-free Returns

All orders are covered by our 45-day Hassle-free Returns guarantee.

Why Buy From Us?

Safe & Secure

Expert Advice on All Our Products

Selected by Woodworkers, for Woodworkers

Explore The Range

View all

1 million+ reasons to buy from us

Wood Workers Workshop is an online tool shop run by woodworkers, for woodworkers. Delivering 5-star customer service since 1999. Shipping over 1 million premium tools worldwide.

We stock a wide range of quality woodworking tools from leading brands and offer next day UK delivery plus 45 day hassle-free returns.

Let customers speak for us

What customers think about the store

This store offers high-quality woodworking tools and equipment with excellent customer service. Customers consistently praise the quick delivery, careful packaging, and knowledgeable support team. Products arrive well-protected and often exceed expectations fo...