We are delighted to offer a personal demonstration of this machine in our exclusive Harvey workshop. Please contact us for an appointment and to understand why we are excited to be working with Harvey.

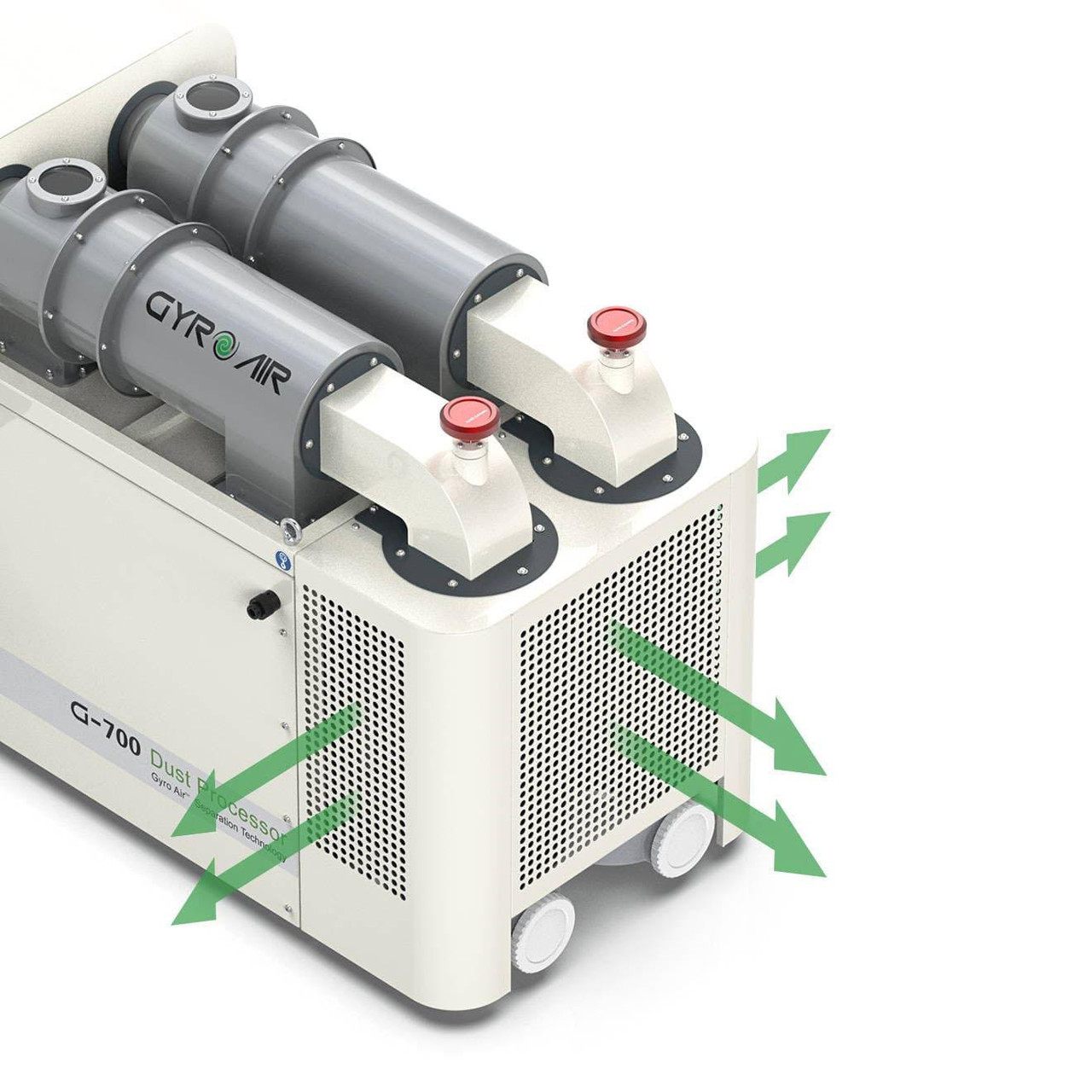

The Gyro Air® Dust Processor is revolutionizing dust collection. Designed with Harvey’s revolutionary axial centrifuge technology (called Gyro Air® Technology) which is completely different to any existing dust collector on the market. The Gyro Air® Technology spins the flowing dust stream at high speeds (over 4000 rpm), which generates a significant centrifugal force on dust particles (a G-force of over 100) causing them to be pushed away from the airflow centre and depositing them into dust tanks. The clean air remains in the chambers and any remaining fine particles are collected in the air filters.

Features Include

- Axial cyclone dust separation system

- 99.97% of dust separated pre-filter

- Very quiet operation 61-72dbA

- Compact size with built-in wheel kit

- HEPA filters 100% > 1 micron

- Filters 99.35% > 0.3 micron

- Industrial variable speed motor

- Collection container full alarm

- Remote control start

- Powder coated steel frame

- Internal paddle cleaning for filters

- 2 x 100mm (4”) diameter inlets

- 2-year warranty

High Efficiency Separation

Blocked filters create a build-up of internal pressure and a huge reduction in performance. This unprecedented new technology outperforms traditional dust collectors and even outperforms newer vertical cyclone systems. The whole concept of the Gyro is to separate the dust from the airflow before it reaches the filter.

It does this in two stages. In stage one the air passes through a pair of double cone chambers which slows down large particles (chips and shavings) for gravitational drop down into the larger collection tank. Stage two generates high-speed spinning of the air through a pair of horizontal chambers at incredible speed, using centrifugal force to push the remaining dust to the outside of the chamber and into the smaller collection tank. The G-700 achieves a separation level of 99.7%. Only 0.3% of the dust ever reaches the filter, reducing the need for frequent cleaning and greatly extending the life of the filters. A quick turn of the internal cleaning paddles once a week is all that is required. A deeper clean is recommended once every 3 weeks which only takes 2 minutes.

High Level Filtration (HEPA)

HEPA grade filtration material filters 100% of dust particles larger than 1 micron. 99.91% of dust particles between 0.5 and 1 micron. 99.35% of dust particles between 0.3 and 0.5 microns. This level of filtration offers complete protection for woodworkers.

Lower Running Costs

The GYRO AIR® Technology includes a VFD speed control system. The rpm speed of the motor is controlled by adjusting the frequency, in the range of 40Hz to 75Hz. This can give operators the benefit of up to 50% reduced energy costs. Sometimes more power is needed: Like when working with high-volume waste machines, like a large planer, or when running dust through a longer ducting system with more bends. In those cases, the speed of the motor can be increased. The rest of the time, turn the speed down and save electricity.

Quite Technology

The GYRO AIR® Technology and its unique aerodynamic design allow the G-700 GRYO AIR® to run at incredibly low noise levels. When running at low speed a noise level of only 61dB(A) is achieved. That is about the same as a normal conversation. Even when running at full speed the noise level is only 72 dB(A), similar to a washing machine.

Extremely Clean Emissions M-Class

The air emission cleanliness level from the filters can reach an unbeatable 0.05 mg/m³. That is 50% better than the European M-Class Standard of 0.1 mg/m³. M-class certification means this extractor meets the HSE standard for medium risk dusts, which includes all kinds of wood dust including softwoods and hardwoods.

Convenient Tool-less Dust Tank Cleaning

The two dust collection containers are easily accessed through a hinged door panel on the front of the unit for emptying. The two containers (one will contain larger particles and chips, the other will contain fine dust) pull forward and roll out for easy emptying. The disposal bags can them be lifted out and replaced with new ones.

A buzzer on the control panel will sound when the collection tanks are full, prompting the operator to empty them.

Performance Monitoring

The G-700 is fitted with a pressure gauge. Once the machine is running at the set frequency, rotate the manometer ring to note the internal pressure. If the pressure is observed to fluctuate, it is a signal that something needs checking. An increase in pressure could be a sign that a hose is blocked. A decrease in pressure could be a sign that there are air leaks in the ducting or other blast gates have been opened.

Includes

- 2 x remote control handsets

- Y-piece with 2 x 100mm inlets

- 100mm to 63mm reducer

- 2 x disposable bags for each tank

- 4Mtr cable with UK 3 pin plug