Titman Edge General Purpose Diamond Bench Stone 8" x 3" - 180/600 Grit

- Warranty: 1 Year & Lifetime Customer Support

- Price Match Promise

- Order by 2pm for Same Day Dispatch – Mon to Fri

- 45 Day Hassle-free Returns

- Worldwide Shipping | No Hidden Costs

Titman Edge General Purpose Diamond Bench Stone 8" x 3" - 180/600 Grit is backordered and will ship as soon as it is back in stock.

Description

Description

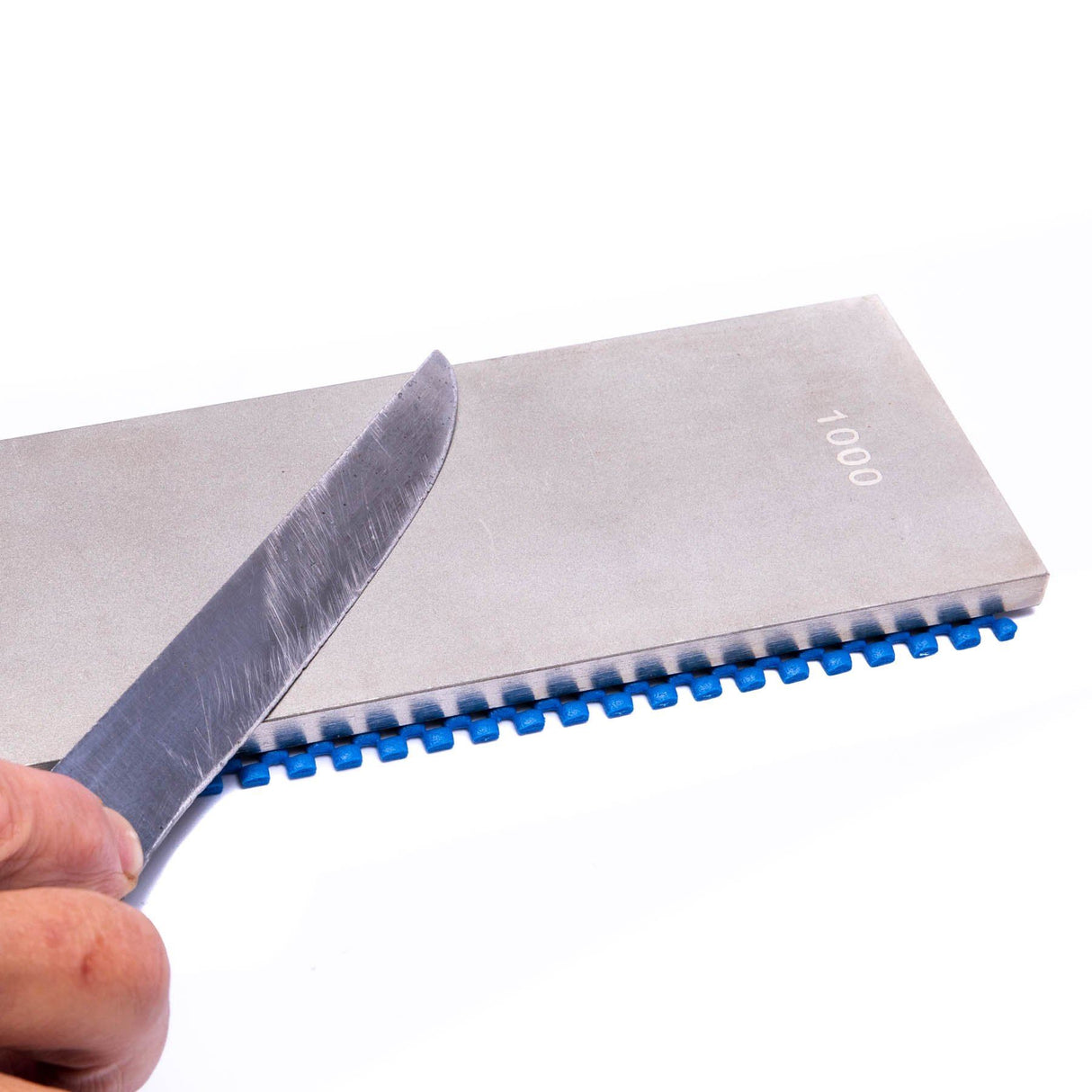

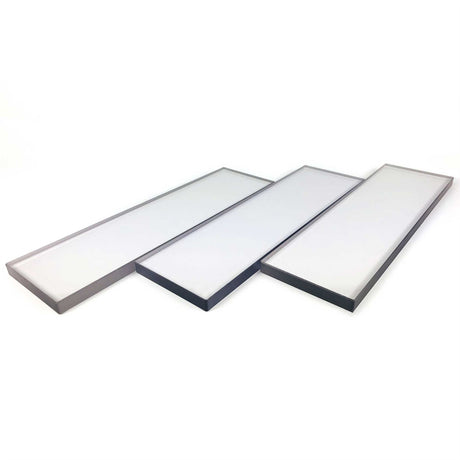

Double-sided diamond bench stone ideal for site work and your workshop. The 180 grit side has unique clearance channels that clear away any swarf/residue following either sharpening or flattening oil and water stones. The 600 grit side is ideal for removal of scratches left after flattening tools such as chisels and plane blades before progressing to fine honing and polishing. The continual diamond surface will produce a quick shaving edge which is perfect for site work.

The precision-ground substrate ground to +/- 0.005" makes it perfect for plane irons and chisels up to 75mm wide

This stone is also a perfect addition for owners who already own the Classic Profession Workshop Stone which has established itself as being a world market leader since its release 18yrs ago by James Barry Sharpening Solutions.

Guaranteed for five years when used with Titman Edge Lapping Fluid.

Features

- Size: 152mm x 50mm

- Extra-coarse 180 grit and fine 600 grit

- Clearly marked grit sizes on the stone's surface

- Storage pouch, cleaning block and non-slip mat

Technical Information

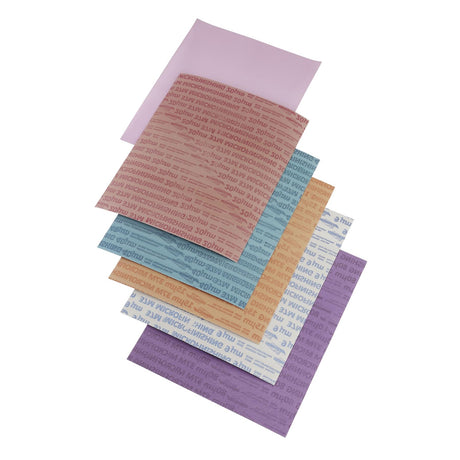

Grit and micron sizes are difficult to translate into traditional grit sizes of water and oil stones. The grit sizes quoted on the following products are accurate to within the parameters of international grading standards which is +/- 11%. Therefore a 25-micron product may consist of diamond particles varying from between 27.5 – 22.5 micron.

180 grit/70 micron 300 grit/50 micron 600 grit/25 micron 1000 grit/ 5 micron

All the products have a breaking in period, there is an excess layer of diamond which needs to be removed before the surface is at its optimum designed sharpening abrasion.

Be careful when breaking in a coarse side (300 grit / 50 micron) to wipe down the tool thoroughly before moving to the fine side (1000 grit / 15 micron) to avoid cross-contamination and therefore taking a much coarser diamond onto a much finer side – it will scratch it!

Once the stone is worn in, you will not need to be quite so thorough as there is no longer a threat of cross-contamination.

The actual cutting medium (micron size of diamond) is actually 1/3 rd of the quoted sizes.

In construction, the precision ground substrate (+/- 0.005” flatness) is placed in a tank of nickel which is heated to a certain temperature. Then an electrical current is added which electroplates the nickel onto the surface. This includes diamond particles. Then the nickel is grown around the particles so that they are buries 2/3rds deep leaving 1/3rd exposed (the designed abrasive cut)

The only way to quote the flatness of a diamond stone accurately is from the substrate only because of the variation of the diamond particles (+/- 11%) and because the new product does have to be broken in.

This is why this range of diamond products is regarded as one of the best available.

The diamond is electroplated directly onto a precision ground substrate.

Both sides are electroplated onto the same precision ground substrate giving the best possible flatness.

The majority of other products are constructed by a “layer” system where a plate is electroplated or impregnated with diamond and then stuck onto some sort of base material, either plastic or steel.

For the best quality, the diamond has to be electroplated directly onto the surface.

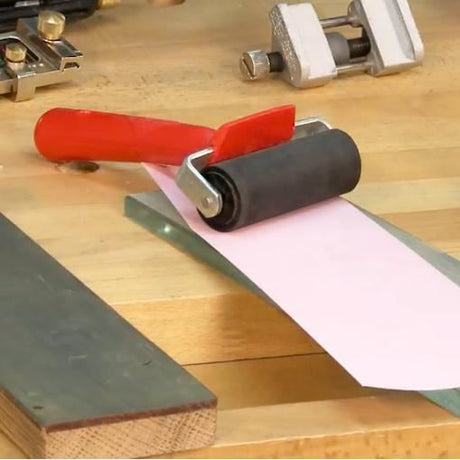

Ensure that you use the Titman Edge Lapping Fluid, the original fluid introduced into the woodworking industry by James Barry Sharpening Solutions some 20 yrs ago. Lapping fluid is a synthetic based petroleum lubricant formulated to be used with diamond compounds.

This superior lubricant, with its penetrating qualities and oil/water solubility, not only increases the cutting action but assures superior lubrication of every diamond particle throughout the honing process.

Delivery & Returns

Delivery & Returns

Same-Day Dispatch

Orders placed before 2pm (Monday–Friday) are usually dispatched the same day. All deliveries are fully trackable.

UK Mainland Delivery Options

| Service | Delivery Time / Notes | Price |

|---|---|---|

| FREE UK Delivery | 1–2 days — orders over £85 | FREE |

| Economy Delivery | 2–3 days | £4.50 |

| Standard Delivery | 1–2 days | £5.95 |

| Express Next Day | Next working day — orders placed by 2pm (Mon–Thurs) | £7.99 |

| Express Pre-Noon | Next working day before noon — orders placed by 2pm (Mon–Thurs) | £15.95 |

| Saturday Delivery | Saturday delivery — orders placed by 2pm Friday | £25.50 |

| Click & Collect | Open for collection: 9am–4:30pm (Mon–Fri) | FREE |

Important information

- Express Pre-Noon and Saturday services aren’t available to Northern Ireland, Scottish Highlands, Islands or remote postcodes — Express Next Day takes 2 days and other services may be slower.

- Large or heavy items may not qualify for Express Pre-Noon or Saturday delivery to your area — we’ll contact you if this applies.

- Click & Collect – Collection available after you receive “Ready for Pickup” email — most orders before 2pm are same day.

International Delivery

We ship worldwide to over 200 countries. No hidden costs — all duties and taxes are calculated at checkout.

Harvey Machines Delivery

After placing your order, Harvey UK will contact you to arrange a convenient delivery date.

Hassle-free Returns

All orders are covered by our 45-day Hassle-free Returns guarantee.

Why Buy From Us?

Safe & Secure

Expert Advice on All Our Products

Selected by Woodworkers, for Woodworkers

Explore The Range

View all

1 million+ reasons to buy from us

Wood Workers Workshop is an online tool shop run by woodworkers, for woodworkers. Delivering 5-star customer service since 1999. Shipping over 1 million premium tools worldwide.

We stock a wide range of quality woodworking tools from leading brands and offer next day UK delivery plus 45 day hassle-free returns.

Let customers speak for us

What customers think about the store

This store offers high-quality woodworking tools and equipment with excellent customer service. Customers consistently praise the quick delivery, careful packaging, and knowledgeable support team. Products arrive well-protected and often exceed expectations fo...